TBC Console Table FREE Plans

So I made a thing… and Desert Woodworks built it! The Builder’s Challenge has teamed with with Osborne Wood and we had them create an exclusive TBC Edition Wooden Table Leg that we want to see you guys use in your builds!

The TBC Table Legs

First, let’s talk about the Osborne table legs. We fancy over at the TBC and we’ve had the legs triple fluted on two sides. Why only two sides? So you can attach aprons or supports and not worry about butting a joint up against them. They are 2-1/2″ x 2-1/2″ thick and 29″ tall made out of knotty pine, so you can paint or stain these.

The TBC Console Table

This is a beginner build with a slightly more difficult table top that you can alter, but we’ll show you how to knock a Chevron style top out the easiest way. You can add a shelf on the bottom or drawers to the front but most importantly, it’s an easy win for a great looking piece that has elements from rustic to modern.

Tools & Supplies Needed

- Circular Saw

- Miter Saw (you can substitute with a circular saw and a speed square since all cuts are 90 or 45 degree)

- Drill/Drill Driver

- Pocket Hole Jig (as an alternative to traditional joinery)

- Pneumatic Nailer

- Wood Glue

- 1-1/4″ pocket screws

- 2-1/2″ pocket screws

Cut List

- (2) 2 x 2 x 11″ boards (bottom support)

- (1) 2 x 2 x 47″ board (bottom support)

- (2) 1 x 6 x 11″ boards (top apron)

- (2) 1 x 6 x 11″ boards (top apron)

- (1) 1 x 6 x 13-1/2″ board (top divider)

- (1) 3/4″ x 16″ x 52″ plywood sheet (table top base) *see tip in step 3

- (2) 1 x 4 x 52″ boards (table top trim)

- (2) 1 x 4 x 17-1/2″ boards (table top trim)

- (X) 1 x 4 x varied lengths (table top pattern)

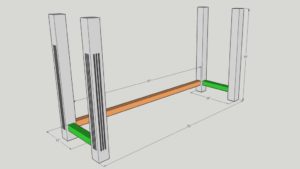

Step 1 Leg Supports

Cut the 2×2’s down to 47″ and two at 11″ for the bottom supports. For this build you can use pocket holes set to a depth of 1-1/2″ and pre-drill on the bottom side of the 2×2’s. Notice the fluting on the table legs is facing outward. Attach the bottom of the 2×2 supports 2.5″ from the bottom of the table leg running even with the start of the fluting. The supports are also centered to allow for 1/2″ spacing on each side. Be sure to add wood glue in your joints before attaching the 2-1/2″ screws.

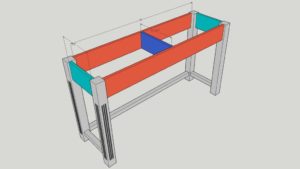

Step 2 Top Supports

Cut two 1×6’s to 47″, two more to 11″ and one to 13-1/2″ for the top supports. Pre-drill 3/4″ pocket holes on the inside face of the aprons on the ends that will attach to the legs. If you’re feeling extra ambitious pre-drill several more 3/4″ pocket holes along the top edge to attach to the 3/4″ sheet of plywood being used as the base for the table top. Attach the aprons leaving the same 1/2″ spacing from the outside edge of the table legs using 1-1/4″ pocket screws and wood glue. Add the center divider as well.

*Desert Woodworks modified her piece and added length to the console.

Step 3 Table Top Base

Instead of buying an entire sheet of 3/4″ plywood and having a ton of leftovers, I recommend buying project panels (2’x4′ smaller sheets of plywood) and cutting them down to 16″ x 26″. They’re easier to transport and you don’t have to deal with a giant sheet of plywood. You can also get the cheapest 3/4″ type of plywood since this will be hidden by the actual table top. Attach from underneath with the pre-drilled pocket holes in the aprons in step 2 or drill down from the top and counter-sink.

*If you’re painting or staining the piece a different color than the table top, this is the time to do it.

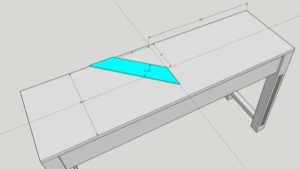

Step 4 Table Top Patterns Made Easy

The trick to being successful with angled cuts is to make sure everything ends up being the same angle. In this case we’re cutting everything on 45’s. Draw a center line in both directions on your sheet of plywood at 8″ and 26″ to mark the start of your pattern. Cut your first 45 degree angle on your 1×4 that will be your first piece (don’t make the second cut yet, you can leave a couple extra inches on if you don’t want to have a full board) and line up the inside corner with your mid-line intersection.

What I personally like to do here is then draw the outline of each piece onto the table top so I can see what my pattern is going to look like before I make cuts and attach it all. For cutting and measuring the pieces, you actually don’t need to be exact. You can either cut your initial 45 degree for each piece and line it up with where it meets the center line or one of the outside edges and cut off the excess on all edges with a ledger board and a circular saw. OR you can lay your pieces out and mark the underside using the outer edge of the table a guide and go back and cut.

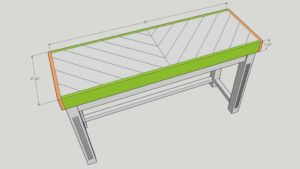

For attaching the pieces you absolutely want to use wood glue on the bottom and a small amount on the joined edges, but I also like to use a pneumatic nail gun and attach directly from the top. Keep in mind that you can also pre-stain or paint the pieces for you attach them as well.

After your top pattern glue has dried and all the edges are evenly cut (check out this post about to do with overhang if you’ve got a router and a little excess material) it’s time to trim out the table top. Cut two 1 x4’s to 17 1/2″ for the ends and two more to 52″ for the sides. Run glue along the edge and tack in the sides and ends to the table top with your pneumatic nailer. I like to use a round over bit with a router on the edges but you can also break the edge with a Random Obit Sander so your corners aren’t too harsh.

Desert Woodworks finished her build by distressing the wood and adding a custom stain. It found a home in her large entry way and fits the space perfectly.